Engineers at MIT and in China are aiming to turn seawater into drinking water with a completely passive device that is inspired by the ocean, and powered by the sun.

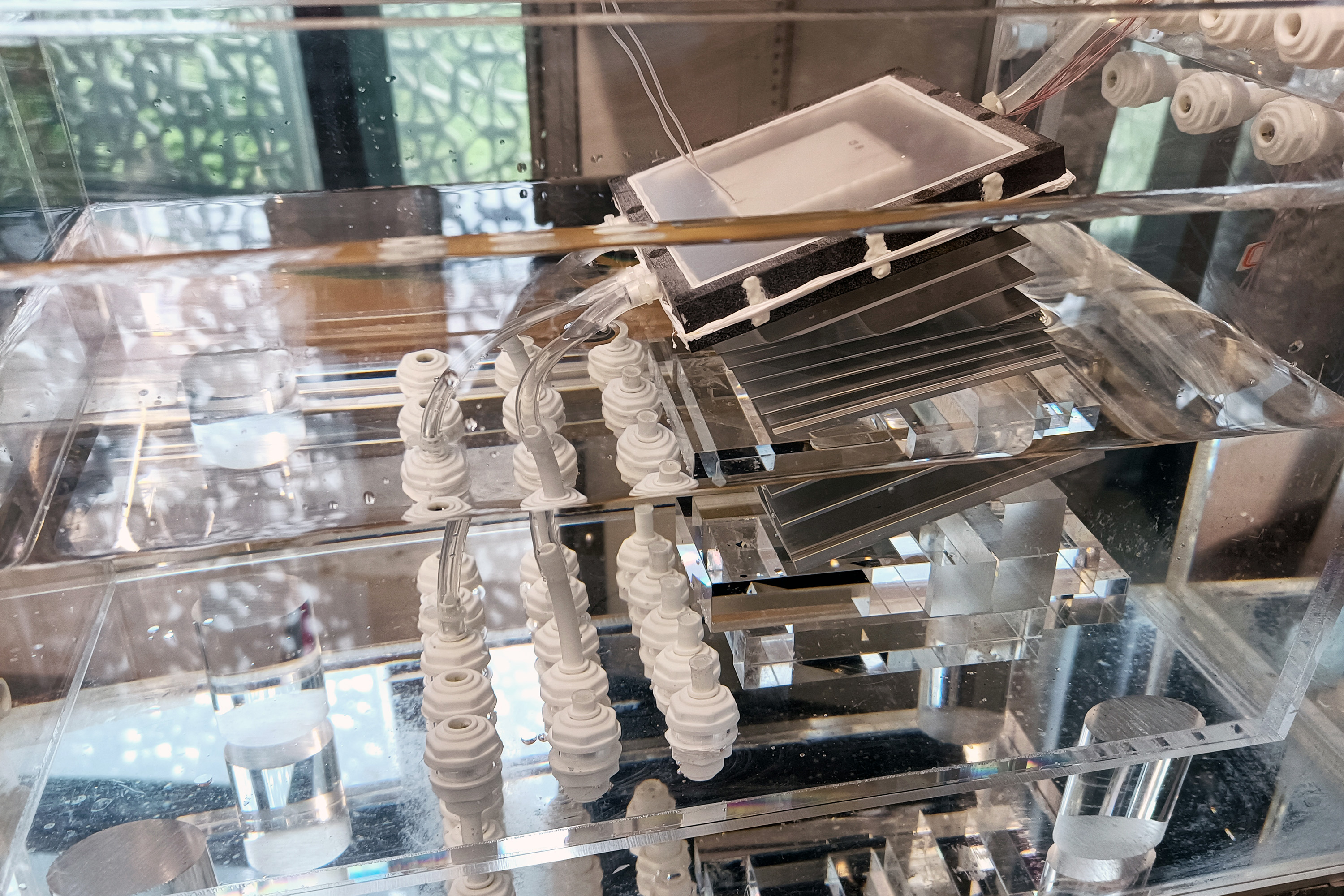

In a paper appearing today in the journal Joule, the team outlines the design for a new solar desalination system that takes in saltwater and heats it with natural sunlight.

The researchers estimate that if the system is scaled up to the size of a small suitcase, it could produce about 4 to 6 liters of drinking water per hour and last several years before requiring replacement parts. At this scale and performance, the system could produce drinking water at a rate and price that is cheaper than tap water.

Years ago they said that the screen lense from discarded projection TVs could boil/desalinate water with nothing but sunlight and discarded junk. They could literally create entire desalination plants with nothing but junkyard scrap. They never did anything with that.

I think all these “desalination” projects are nothing but worthless attempts to get free money for research

What’s wrong with desalination research? Water is essential to life, and most water on Earth is salinated. The practical value of this research is apparent, both for ships on sea and coastal regions. So I don’t see how these attempts are “worthless”, and how it would be bad if they receive more “free money”.

The article talks about what could have been a challenge faced by the junkyard scrap model, and how they solved it:

I’m not sure how much money is in desalination, but it’s certainly an industry. If a group comes up with a new method, and then nothing happens with it, it’s probably because it’s either not that great after all, or not that cost effective.

Maybe a problem is that the countries where it’s needed the most are not exactly the richest countries: https://ourworldindata.org/water-use-stress#what-share-of-freshwater-resources-do-we-use

you know, if you build a large solar still, you just have to flush it every couple cycles to deal with the salt, and it can be as big as you can make a warehouse…

How do you know that you’re flushing out all the salts with each flush? Are you able to reach every part of the reservoir with the flush? Even if you can, what do the flow patterns look like – are there dead zones with no flow?

It really isn’t as simple as you describe, although I really wish that it was.

So the fun part is, all of what you mentioned, doesn’t matter, because you don’t actually need to get every bit of salt out of the reservoir, so you just flush out a good deal of it with more salt water!

you read this paper and its complexities and assumed that the things mentioned are inherently important to the functioning of the system, but like the Tesla-trucks and acceleration, they really aren’t.

all you need for the system to work is liquid, as long as there is more osmotic pressure pulling the water away from the salt than the hydrogen bonds produce.

low tech, easy to scale, and already being done

Yes and no. I get what you’re saying. No wash is 100% efficient, nor does it have to be. It’s just going to set the number of runs the unit can do before it needs to go offline for more intensive cleaning. Short run times though lead to more expensive operation. What this work does is increase the run time by more efficiently removing salt.

Do you get what I mean? Long term salt buildup is going to cause problems, and the more slowly you can make that happen, the better.

salt is not limestone

What does that have to do with anything?

limestone deposited by water leads to a hard, not easy to remove build up as it will not readily redissolve into any water, unlike salt, that will gladly let its self be dissolved via osmotic pressure until the maximum salinity of water is reached

seawater for example has around 34-35 ppt salt, water is satisfied at around 260ppt, meaning that one saltwater flush of the system will clean out basically all the salt of like 7 prior runs

For desalination all you need is a glass bowl and two metal bowls. You put the bigger metal bowl on the ground, the smaller metal bowl in the middle, and the glass bowl over the little bowl. The salt water evaporates from the little bowl and condenses down the glass bowl into the bigger bowl. You can run this setup pretty much forever, there’s no moving parts and minimal maintenance. That’s how simple desalination is. All solar desalination projects work on this principle.

The reason we don’t use it is the same reason we don’t do so many things: there is no immediate monetary cost to destroying the environment and using up common resources, so desalination is “expensive” compared to just using up the groundwater. Once all the groundwater is used up and the rivers run dry, desalination will be very competitive.