I’m trying to find out what purpose this type of design serves and how they are designed but have hit a wall with knowing what to even look for.

This piece of the voron stealthburner is the only example I can think of off the top of my head but I have seen them before in some sort of fan duct or funnel thing.

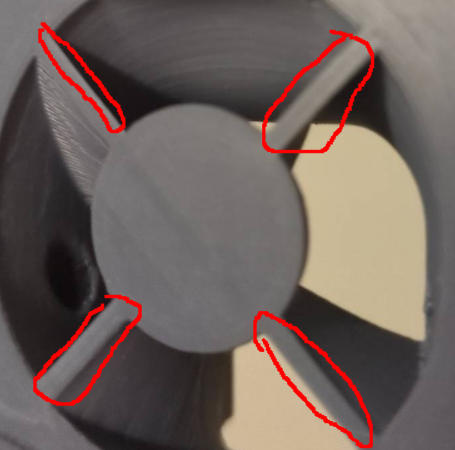

just to clarify, you’re talking about the bits whose ends are marked in red circles?

They’re called stators. In a ducted fan (or similar) they’re used to control the air flow coming off the fan. Usually, it’s fairly turbulent airflow, with a bit of spinning going on. the stators are used to make that turblent flow more smooth and laminar.

I’m not sure why they have it on the Voron- I assume that’s the fan that cools the hot end heat sink, in which case turbulent flow is not a problem at all. It could be to reduce noise and act as a fan guard, though. Or it could just be cosmetic. probably bit of the last two.

They discuss it in some detail in one of the Voron Live talks - I think this one, which was the announcement video for Stealthburner. Lots of CFD combined with manufacturability testing and aesthetics mixed in too.

Edited to add: oh, that’s the hot end fan. I don’t remember if they discussed that or just the part cooling fan, but the video is an interesting watch either way.

Oh yeah. They put a lot of thought into it. I’d say it’s probably one of the more over engineered bits… but they’re all kinds over engineered… heh.

Sorry I wasn’t as clear as I thought. I mainly meant the cone part but that also is of interest.

The cone shaped hub in the middle? Same reason you’d see a pointed nose or tail on a plane, to reduce drag and turbulence and possibly noise. With some fans it doesn’t really matter but at high enough flows it’ll become worth it to spend the extra money on that part to make it cone shaped.

Look at airplane propellers. On them that part is called a spinner. On an old, slow, biplane with tons of cables and other draggy parts, it likely wont have one because it’ll make no difference anyway. But on anything that’s the slightest bit sleek you’ll have one because it will significantly reduce drag.

I guess it’s 3d printing so I can just try it and see and redesign if I don’t like it. I have a couple old ek vardar fans that are stupidly loud and finger chopping fast rpm.

The hub mostly reduces turbulence in the flow as well. Depending on if it’s on then intake o exhaust , it also has a number of effects.

As an intake, it compresses the incoming flow, as it comes to the blades with less drag- which makes the fan much more effecient.

As an exhaust, does the same, but would also expand the cross section (which slows the airflow,) it looks like the duct also constricts, though, so rather than changing the speed of the airflow, it’s removing the center void created by then fan’s own hub.

Which again smooths out the flow and makes it more effecient for whatever it’s hitting

What exactly are you trying to do, if you don’t mind my asking?

Just trying to quiet those loud fans?

Started out ducting various things to other things such as fan to radiator, computer exhaust to outside, or to hanging wet clothes, etc. Then I got rabbit holed into research on different types of fans and how blades and rpm and fan dimensions change various things. A few prints and some purchased fan gadgets had the cone and blades thing and not knowing the names of them has made research difficult. My photo is a hotend heatsink+fan mount and probably the smallest example of this concept I have seen.

Most of the things I am thinking of making would originally performance first but if sound can be reduced by a measurable amount it would be worth testing.

Ah. So yeah like the other person said those static blades are stators. I havent found a good name for the cone aside from “aft cone” but that’s more for turbines. The stators should help it make pressure (that’s what they do in turbines) but the only reason I see for the aft cone is reduction of turbulence and since this is for cooling the hot end turbulence is actually a positive thing because it reduces the skin of hot air that sits against the heatsink fins.

If you’re pusing enough air you may benefit from a nose cone but it should probably be more hemispherical. Also an intake cone that’s like a trumpet bell might be beneficial.

For noise, most is probably in the blades but you may see some reduction by adding a sweep to your stators and/or adding a jaged pattern in some places like all the new jet engines do. Like this: https://www.nasa.gov/wp-content/uploads/2015/03/qtd2_sunrise_3024x2016_0.jpg

Granted, on the scale we’re talking here all of this will be splitting hairs.

Which part of it do you mean, exactly? The narrowing? That funnels air so it moves faster.

The cone shaped part.

I haven’t looked into this specific design and I’m no CFD expert, but I have played with designing and built several small empirical test setups to compare and contrast various designs for shrouds.

Don’t put trust in CFD. These little fans are turbulent flow regime and nowhere near laminar. These two flow regimes are completely unrelated and laminar flow simulation is not relevant in the slightest. You can get turbulent CFD simulation software but they all cost many thousands of dollars as far as I am aware. The last time I went down this rabbit hole was a year or more back.

The boundary flow effect is a major factor in airflow, as is the total length of the system. The rough printed surface area of this design is likely hurting the total flow. Any sharp face angle transitions will cause eddies to form.

The deeper you get into real airflow design, the more you will find that almost everything in the 3d printing space is wrong. The best source of intuitive information I found was looking for info about HVAC duct systems in large buildings. You will find a good bit of info in that space from qualified engineers and academics, and HVAC duct flow is all in the turbulent regime.

Long before I got into 3d printing I was into hotrods and also worked for a bit at some machine shops building engines and porting heads. I was into trying to understand airflow in intakes, heads, and manifolds. I’m still no expert, but I can look at a design and see, intuitively it doesn’t align with all of the super engineered stuff I’ve come across. I know that is super subjective, but like I said, the HVAC space can produce good info and rules of thumb equations about duct length, transition losses, and the impact of surface roughness on the boundary layer. Any basic info in these areas will make almost all designs in the 3d printing space seem like nonsense.

This guy’s got the facts straight. Some 3D printers are in fact reasonably optimized, but also have to contend with pricing by way of complexity slowing down each print, plus post-processing… Easiest thing for most people to do is add a bigger fan. There will be a few situations where that’s not possible.

Thanks. I’m still in the not even knowing what I don’t know level on the topic so that helps my future researching.

New Lemmy Post: Does anyone know what to call this sort of fan optimization or have any reading material on how it works or how to design them? (https://lemmy.world/post/9426132)

Tagging: #3dprinting(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md